30 Years of Trust and Quality

Discover Turan Borfit Products

Contact Us for Customized Solutions

Proud to be the industry’s leading brand since 1995, we consistently put customer satisfaction first.

Our durable and user-friendly products, crafted with the latest technology, offer the highest quality solutions to meet your needs.

Our experienced team is ready to deliver the most effective solutions for your projects. Request a quote today or reach out to us for any inquiries.

TURAN BORFİT develops innovative and high-quality products for domestic, industrial, and infrastructure applications in plastic pipe systems. From irrigation systems to large-scale infrastructure projects, the company offers a wide range of durable and environmentally friendly piping solutions, ensuring long-term performance for its customers.

Turan Borfit Product Group

We are pioneers in the industry with our quality pipe connection systems and innovative solutions. Discover our products.

Electrofusion Fittings

High-quality electrofusion fittings for safe connection solutions in water and gas pipelines.

Injection - Convection - Kit & Fittings

Professional solutions for pipeline connections with injection and convection kit fittings.

Steel Transition - Flanges & PP Coated Flanges

Perfect solutions for different material connections with PP coated steel transition flanges.

Polyethylene Pipe Butt Welding Machines

Safe and durable connections with polyethylene pipe butt welding machines.

Polyethylene Pipe Electrofusion Welding Machines

Easy and safe pipe connections with electrofusion welding machines.

Welding Equipment

Solutions that make your work easier with professional pipe welding equipment.

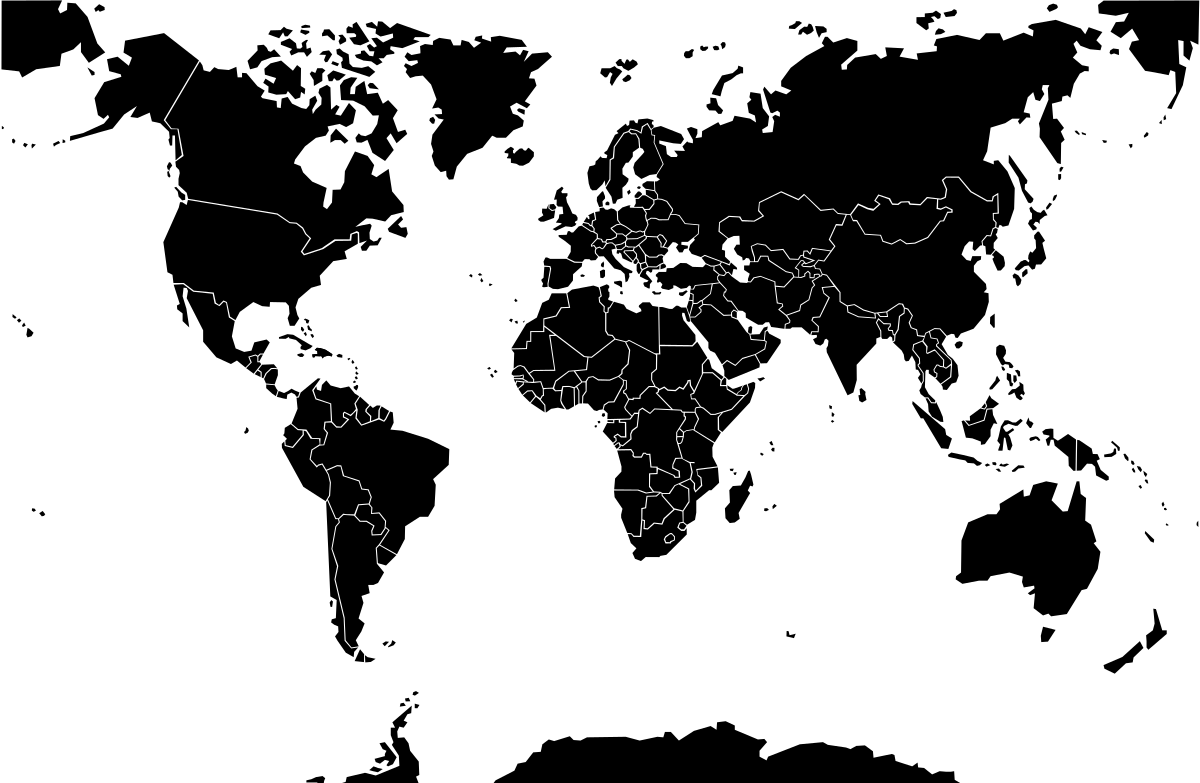

Turan Borfit Products Around the World

Turan Borfit products, safely used in over 70 countries, are the pride of Turkish engineering in the global market

Technical Documentation

Single-point access to all technical documents and resources for the Turan Borfit product family

Product Catalogs

Catalogs containing technical specifications and application details of our entire product range

View CatalogsQuality Certificates

Our compliance documents and quality certificates meeting international standards

View CertificatesProduct Catalogs

Catalogs containing technical specifications and application details of our entire product range

View CatalogsQuality Certificates

Our compliance documents and quality certificates meeting international standards

View CertificatesFrequently Asked Questions

Answers to the most curious questions about Turan Borfit products and services

Quality Assurance and Testing Methods

Turan Borfit products have ISO 9001 Quality Management System, ISO 14001 Environmental Management System and ISO 45001 Occupational Health and Safety Management System certifications. We also produce in accordance with international EN 1555, EN 12201 and ISO 4437 standards.

Our products go through a three-stage testing process: Raw material input control, process control during production and final product tests. More than 50 different tests are applied including hydrostatic test, impact test, leak test and longevity tests.

Under standard usage conditions, the average lifespan of our products is 50 years. Our HDPE pipe systems are made from materials with high UV resistance and provide trouble-free service for many years in underground and above-ground applications.

Product Technology and Features

Electrofusion welding is a method of heat welding between pipe and fittings. Advantages include high leak tightness, low energy consumption, fast application and long life. It is the safest connection method especially for gas distribution systems.

HDPE pipes are corrosion resistant, flexible, lightweight, long-lasting (50+ years), impact resistant, have smooth inner surfaces (low friction loss), allow leak-proof welding and are environmentally friendly.

Our standard HDPE pipes are suitable for use between -40°C and +60°C, while our specially produced PE100RC pipes can be used between -50°C and +80°C. For gas applications, the recommended operating temperature is between -20°C and +40°C.

Application and Installation

Yes, electrofusion and butt welding operations must be performed by Turan Borfit certified operators. Our company regularly organizes welding operator training and certification programs.

A minimum of 80 cm is recommended for gas lines and 60 cm for water lines. This depth should be increased in areas with traffic load. Laying warning tape over the pipe is mandatory.

Technical Support and Services

Yes, under Turan Borfit Academy, we regularly organize product trainings, welding operator certification programs and field training. You can contact your regional sales representative for training requests.

We provide field engineering services on a project basis. Especially for large-scale projects, pre-application site inspection, determination of welding parameters and technical support during application are provided.

WOULD YOU LIKE TO JOIN THE RAPIDLY GROWING TURAN BORFIT FAMILY WORLDWIDE?

WE WOULD BE DELIGHTED TO WORK WITH YOU AS OUR VALUED CUSTOMER.